Filling Composites in the Dental Industry

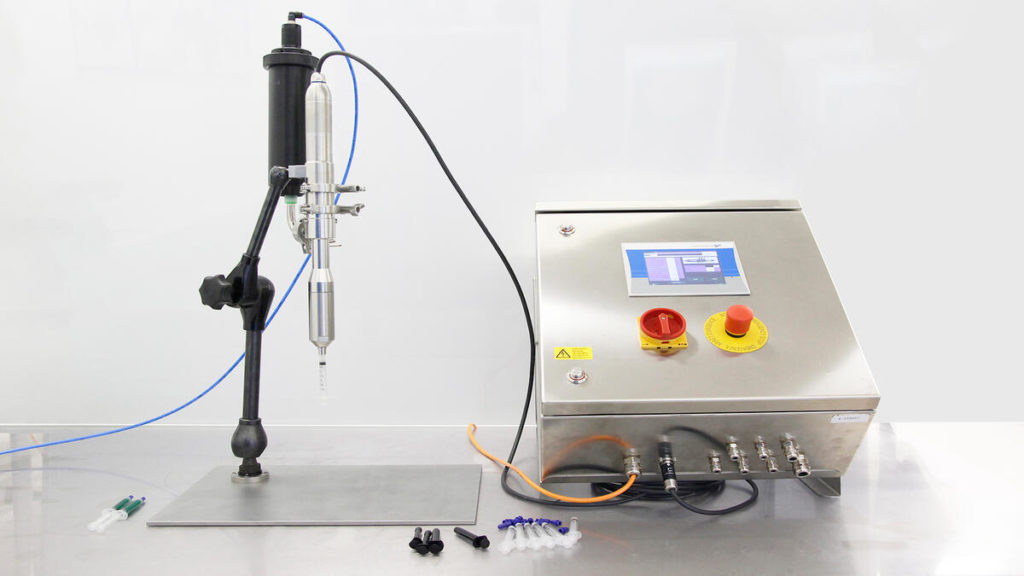

Semi and fully automatic processes save time and material In the dental industry, consumables such as composites are filled into disposable syringes with Luer Lock attachment or into smaller Unit Dose packages. These flowable filling materials made of plastic and glass are usually highly abrasive,…

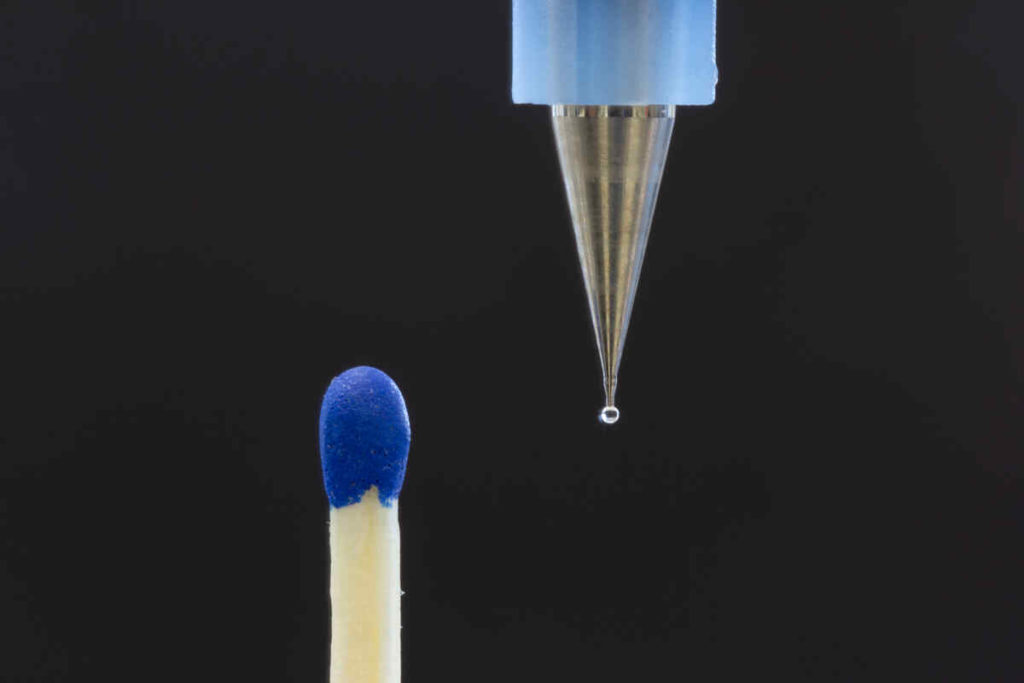

Distance between dispensing needle and substrate

If the distance between the dispensing needle and the substrate is too small it will result in undesirable dispensing results such as flattened bead geometries, adhesion on the dispensing needle or even dripping of the needle during dot dispensing will occur, which can have a…

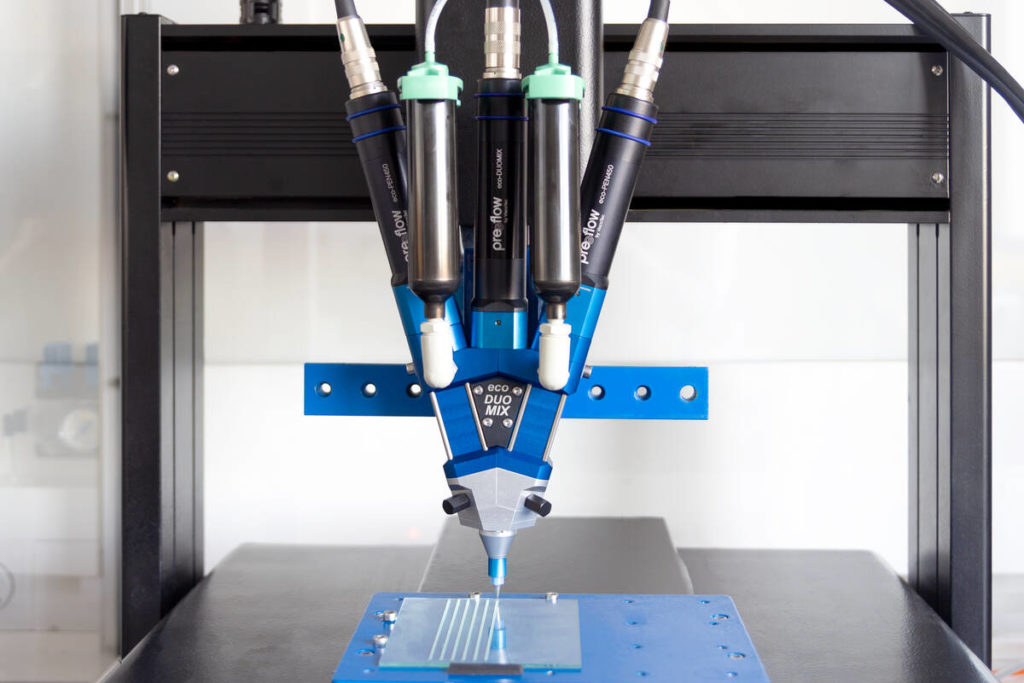

A Variety of Dispensers for Micro Dispensing Applications

https://www.youtube.com/watch?v=Zwt3ogmKueY Covering the entire production process with one technology Dispensing small and smallest quantities with volumetric precision and speed often presents major challenges for companies in the medical technology, automotive, electronics, biochemistry, and photonics industries. It is not uncommon for industrial manufacturing companies to integrate…

NEW: Inliner hose for flexible, effective production

In the cosmetics sector, ViscoTec barrel extraction solutions are often used to feed highly viscous products such as mascara to filling stations. While the emptying and dosing systems can be easily disassembled for cleaning, this does not apply to the hoses in use. This is…

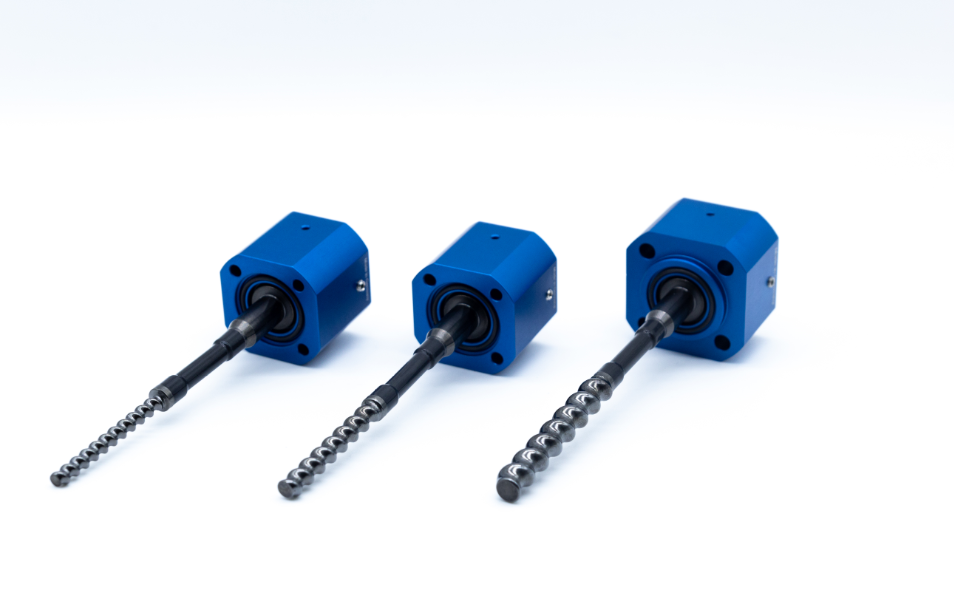

„Diamond Coated Rotor“ for preeflow

A new standard in the micro dispensing of highly abrasive Materials within the 1-component and 2-component range Precise, repeatable, and process-safe applications in the field of micro dispensing have always been the emphasis of the preeflow by ViscoTec brand. Thanks to the volumetric endless piston…

Improvement of the dispensing quality by avoiding air inclusions

Improvement of the dispensing quality by avoiding air inclusions With our dispensing tip, we will help you to understand why air inclusions can occur in dispensing or potting processes, what consequences they have and how to avoid them. Process accuracy and repeatability are two of…

Protective Masks Requirements as a Driver for Automated Production

Increased demand for eye and eyebrow cosmetics requires more flexible and faster production processes for manufacturing and filling of materials. Automation (or partial automation) in certain processes, such as emptying or filling, can be the necessary optimization. Progressive cavity pumps offer great potential, especially when…

Stainless-Steel as an Alternative for preeflow Housing Components

New in the portfolio: Stainless steel kit for eco-PEN 300 to 450 Special requirements require special measures. To meet the requirements of customers and sales partners, preeflow has developed a stainless-steel kit for the eco-PEN dispensers 300, 330 and 450. These alternative housing components are…

Automated Management of Different Viscosities

Production of Soft-Close dampers requires complex dispensing solutions Wherever (vibration) energy has to be dissipated – i.e. where components move – dampers are often used to “buffer” this kinetic energy, e.g. using the viscous behaviour of liquids. The best example of the effect of large-volume…

Rental equipment for a quick and easy start!

Are you searching the market for dispensing solutions? So read on here. You now have the opportunity to rent a dispenser from Scanmaster! This option allows you to test and utilize the latest and most efficient dispensing equipment on the market without much investment required….

Categories

- Animals (1)

- Design (5)

- Dispensers (38)

- Dopag (8)

- Events (3)

- Markets (1)

- Meter Mix (8)

- Music (1)

- News (4)

- Precifluid (4)

- Preeflow (35)

- Travel (4)

- Uncategorized (9)

- Viscotec (40)