Improvement of the dispensing quality by avoiding air inclusions

Improvement of the dispensing quality by avoiding air inclusions

With our dispensing tip, we will help you to understand why air inclusions can occur in dispensing or potting processes, what consequences they have and how to avoid them.

Process accuracy and repeatability are two of the most important aspects of the automated manufacturing process.

During commissioning, container changes or after cleaning, air can enter the system and reduce the quality of the dispensing result.

The required adhesive, sealing or protective effect of the applied material can be reduced by these air inclusions which means that they must be avoided completely.

To avoid air inclusions, appropriate material treatments can be applied upstream, such as degassing a cartridge with a centrifuge.

The material can also be degassed inline with product solutions from ViscoTec, such as ViscoTreat

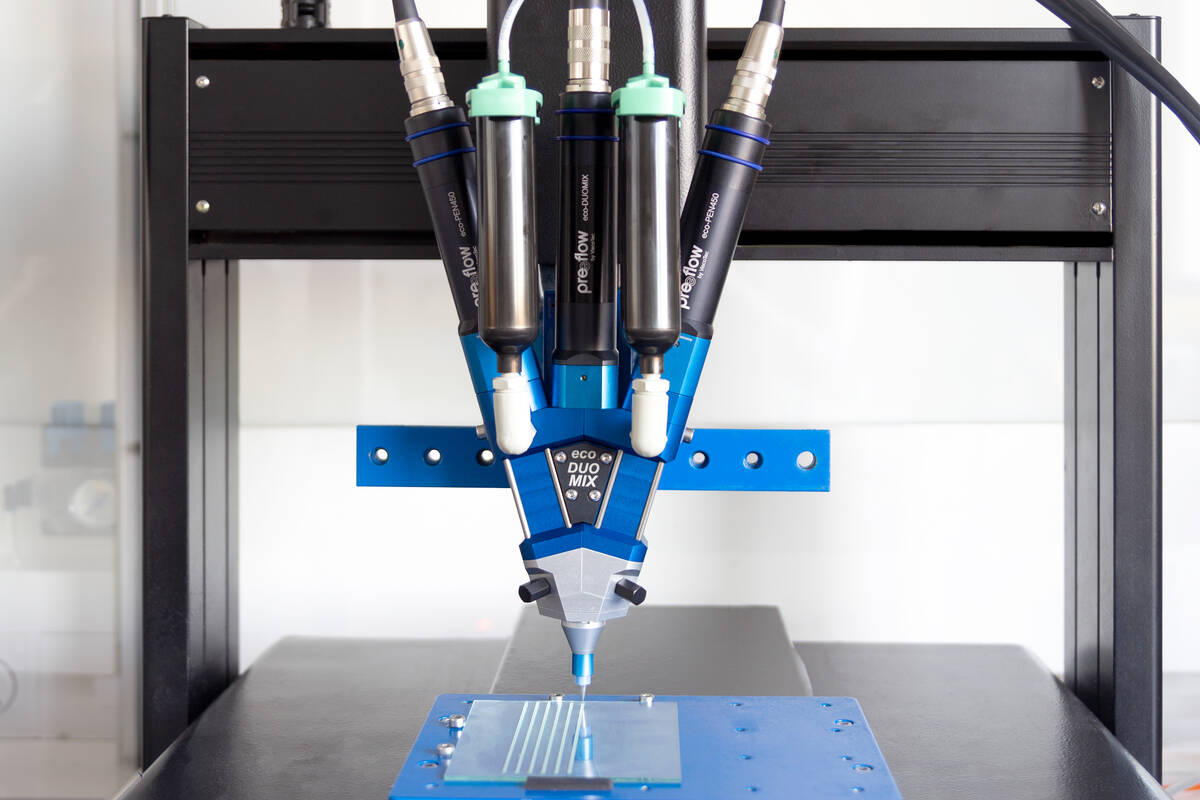

First, the dispenser must be vented properly so that no air is transported

Since our dispensing systems do not produce air inclusions, it is important to bleed the dispenser according to the operation and maintenance instructions.

During initial commissioning or after complete cleaning of an eco-PEN, the air in the dispenser or in the conveying line must be removed.

Proceed as follows:

Connect the dispenser to the material supply.

This can be a cartridge or a supply line coming from a pressure tank, for example.

If possible, move the dispenser to a position where the end piece is pointing upwards to facilitate the air escape.

Tip: An attached hose enables a clean procedure.

Apply pressure to the material and start the drive unit.

Now continue dosing with the dispenser until the material in the hose emerges without visible bubbles.

The dispenser thus successfully vented.

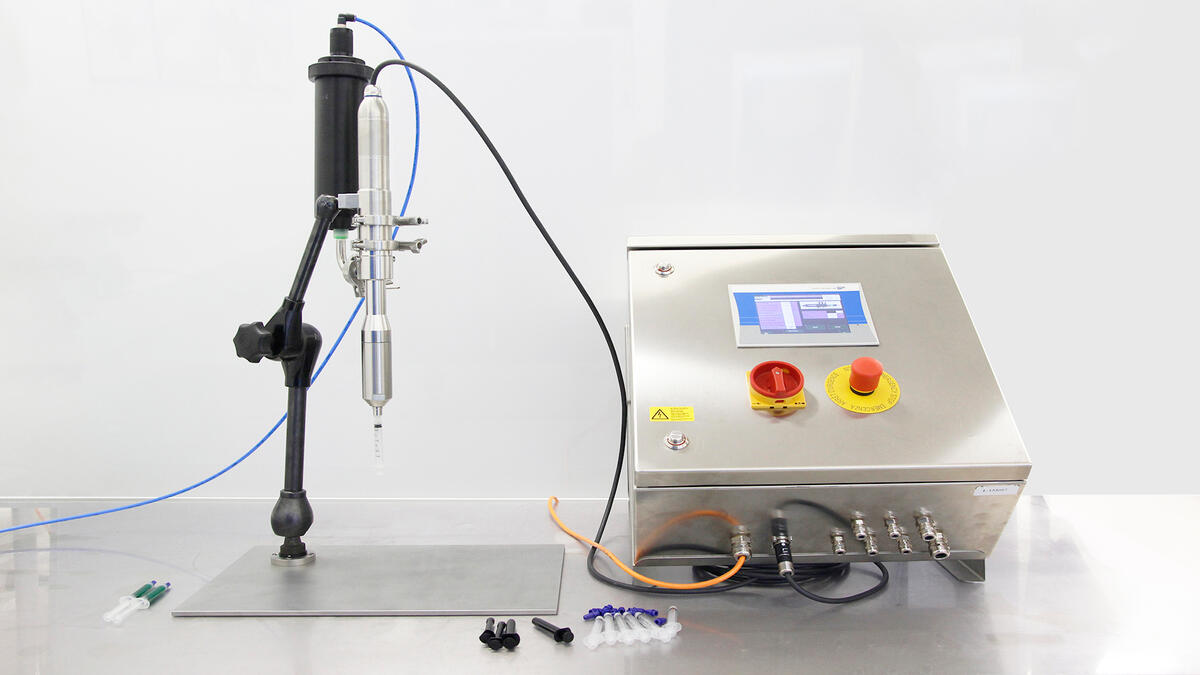

When changing a cartridge, we also recommend bleeding the system.

This is facilitated by the preeflow cartridge adapter.

Change the cartridge.

Put a hose on the cartridge adapter and apply pre-pressure to the material.

Then open the bleed screw until the material escapes without bubbles.

We wish you much success with your application and hope that our dispensing tip could help you.

If air bubbles occur despite proper venting, please contact us.

You can find more information on our website. With our dispensing tip, we will help you to understand why air inclusions can occur in dispensing or potting processes, what consequences they have and how to avoid them.

Process accuracy and repeatability are two of the most important aspects of the automated manufacturing process.

During commissioning, container changes or after cleaning, air can enter the system and reduce the quality of the dispensing result.

The required adhesive, sealing or protective effect of the applied material can be reduced by these air inclusions which means that they must be avoided completely.

To avoid air inclusions, appropriate material treatments can be applied upstream, such as degassing a cartridge with a centrifuge.

The material can also be degassed inline with product solutions from ViscoTec, such as ViscoTreat

First, the dispenser must be vented properly so that no air is transported

Since our dispensing systems do not produce air inclusions, it is important to bleed the dispenser according to the operation and maintenance instructions.

During initial commissioning or after complete cleaning of an eco-PEN, the air in the dispenser or in the conveying line must be removed.

Proceed as follows:

Connect the dispenser to the material supply.

This can be a cartridge or a supply line coming from a pressure tank, for example.

If possible, move the dispenser to a position where the end piece is pointing upwards to facilitate the air escape.

Tip: An attached hose enables a clean procedure.

Apply pressure to the material and start the drive unit.

Now continue dosing with the dispenser until the material in the hose emerges without visible bubbles.

The dispenser thus successfully vented.

When changing a cartridge, we also recommend bleeding the system.

This is facilitated by the preeflow cartridge adapter.

Change the cartridge.

Put a hose on the cartridge adapter and apply pre-pressure to the material.

Then open the bleed screw until the material escapes without bubbles.

We wish you much success with your application and hope that our dispensing tip could help you.

If air bubbles occur despite proper venting, please contact us.

You can find more information on our website.

Categories

- Animals (1)

- Design (5)

- Dispensers (38)

- Dopag (8)

- Events (3)

- Markets (1)

- Meter Mix (8)

- Music (1)

- News (4)

- Precifluid (4)

- Preeflow (35)

- Travel (4)

- Uncategorized (9)

- Viscotec (40)